Surface finishing service

Surface finishing is a critical aspect of manufacturing that alter the surface of a manufactured part to achieve certain desired properties. These properties can be aesthetic, functional, or both. Essentially, surface finishing enhances a product’s appearance, improves its performance, and increases its lifespan. By selecting the appropriate surface finishing process, manufacturers can tailor their products to meet specific requirements and customer expectations.

Why is surface finishing important?

- Enhanced appearance:Surface finishing can improve a product’s visual appeal by creating a smooth, polished, or textured surface. This is crucial for consumer products where aesthetics play a significant role.

- Corrosion resistance:Certain surface finishing techniques, like plating or coating, can protect the underlying material from corrosion and environmental damage.

- Increased wear resistance:Surface hardening techniques can improve a product’s resistance to wear and tear, extending its lifespan.

- Improved functionality:Surface finishing can improve a product’s functionality by reducing friction, increasing conductivity, or enhancing adhesion for coatings or adhesives.

- Surface preparation:Surface finishing can prepare a surface for further processing, such as painting or bonding.

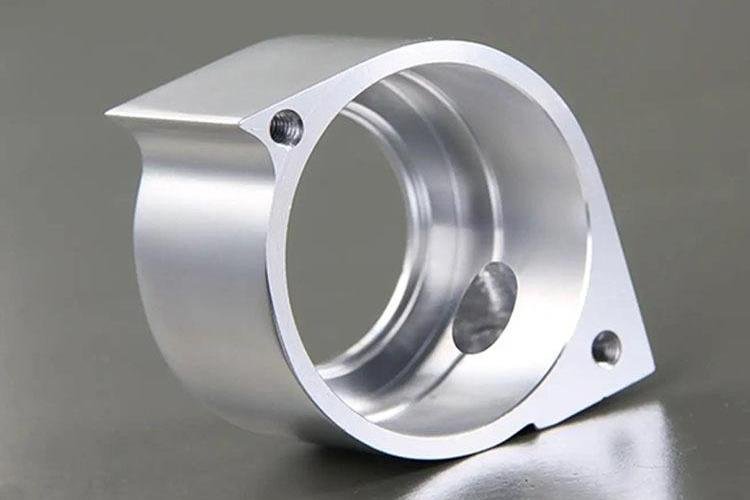

3 & 5 axis CNC milling

XR Precision offers a wide range of milling capabilities, including standard 3-axis mills for straightforward machining, indexed 3+2-axis mills for handling more complex geometries, and fully continuous 5-axis mills for precision multi-axis machining of intricate parts. This extensive selection of milling options ensures high-quality, customized solutions for projects across a spectrum of complexities.

3 & 5 axis CNC milling

Precision machining is a manufacturing process that involves shaping and cutting materials with extreme accuracy and precision. It is used to create parts with very tight tolerances, often measured in thousandths or even millionths of an inch. This level of precision is essential for components used in industries such as aerospace, automotive, medical devices, and electronics.

Common surface finishing processes:

- Mechanical finishing:These processes physically alter the surface of a material.

- Grinding:Uses abrasive wheels to remove material and create a smooth surface.

- Polishing:Uses fine abrasives to create a highly reflective surface.

- Blasting:Uses abrasive media propelled by compressed air to clean or texture a surface.

- Vibratory finishing:Uses vibrations and abrasive media to deburr, clean, or polish parts.

- Chemical finishing:These processes use chemical reactions to alter the surface of a material.

- Electroplating:Uses an electric current to deposit a thin layer of metal onto a surface.

- Anodizing:Electrochemically converts a metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

- Chemical conversion coating:Creates a protective layer on a metal surface through a chemical reaction.

- Coating:Applying a layer of material to the surface of a part.

- Painting:Applying a liquid coating for aesthetic or protective purposes.

- Powder coating:Applying a dry powder that is then cured to form a durable finish.

- Thermal spraying:Spraying molten or heated materials onto a surface to create a coating.

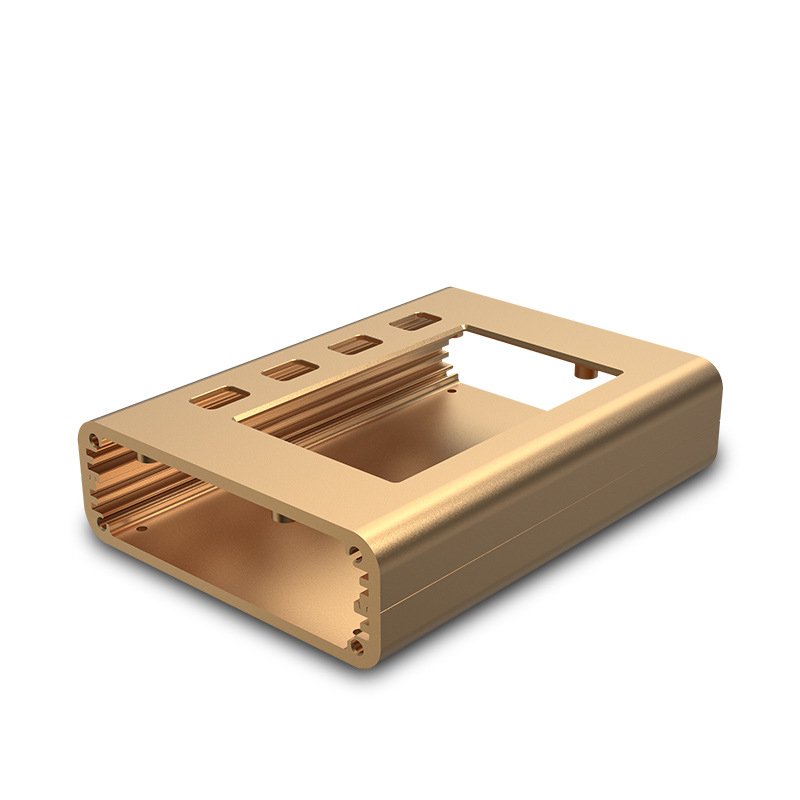

sheet metal fabrication

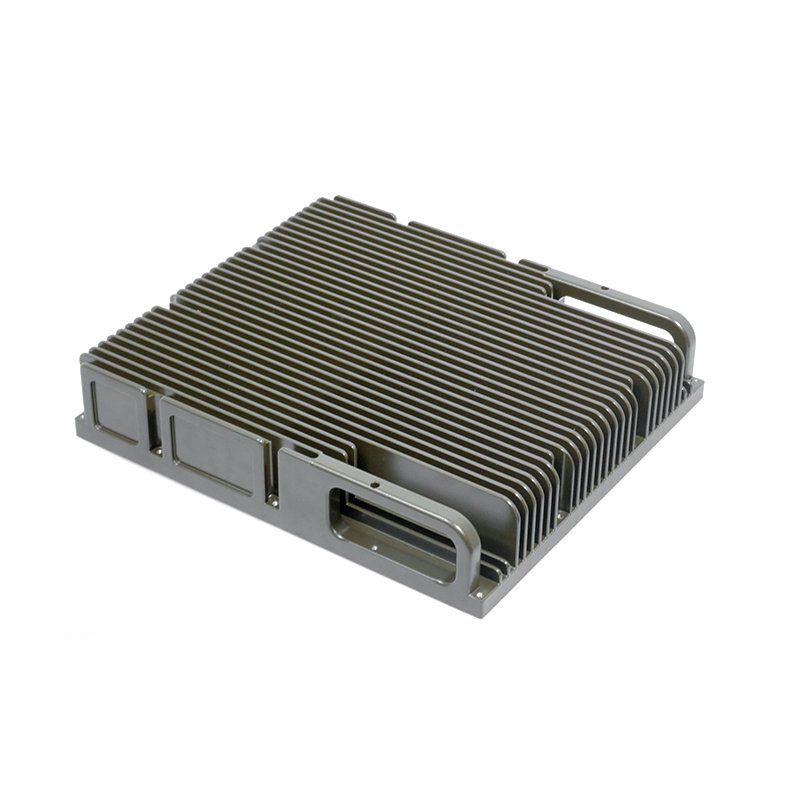

heatsink

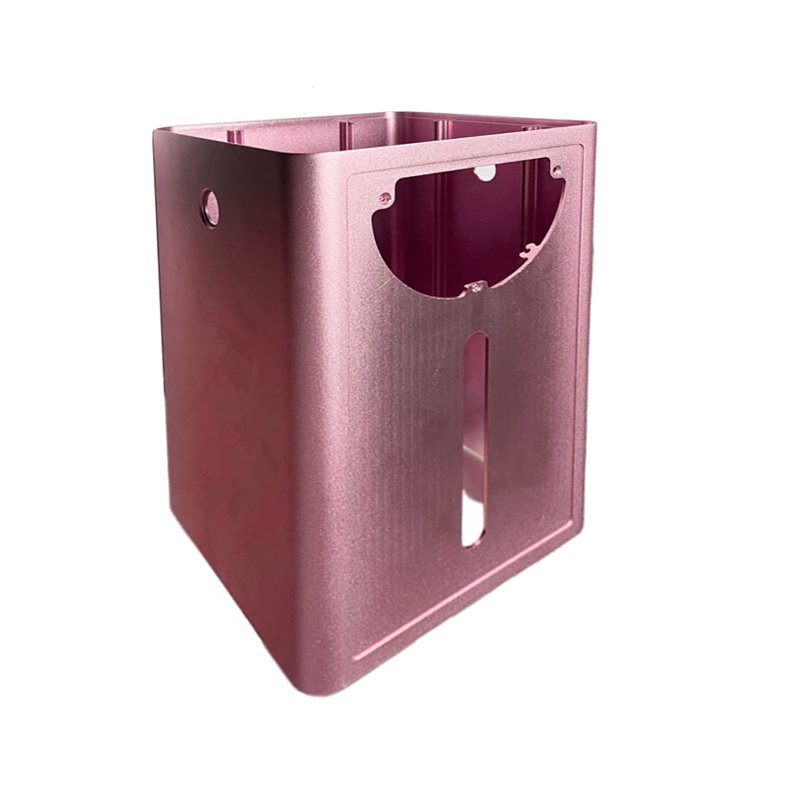

cnc milling parts

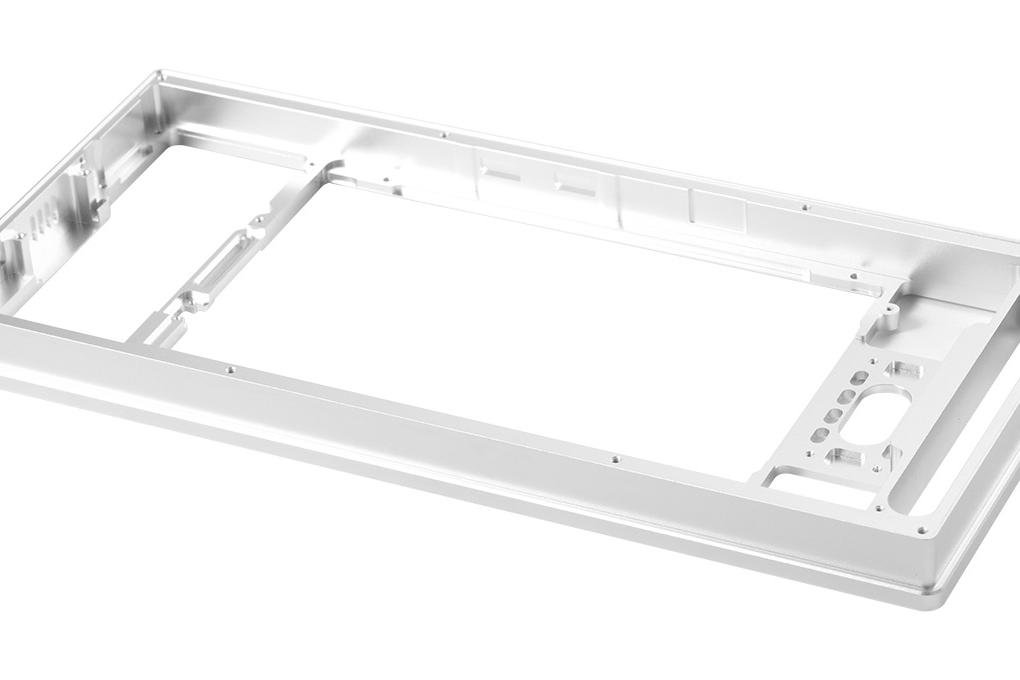

aluminum extrusion 2

aluminum extrusion

Common Metal Surface Treatments

- Polishing: Smooths and shines the surface for an enhanced appearance and smoother texture.

- Painting: Adds a protective and decorative layer of paint to metal surfaces.

- Powder Coating: Applies a durable, even finish using powdered paint, baked onto the metal.

- Anodizing: Creates a corrosion-resistant oxide layer on metals like aluminum for better durability.

- Electroplating: Uses electrical current to deposit a metal coating onto a part for improved wear resistance and appearance.

- Galvanizing: Coats steel with a layer of zinc to prevent rust and corrosion.

- Passivation: Enhances the corrosion resistance of stainless steel by removing free iron and contaminants.

- Brushing: Creates a textured, matte finish by rubbing the metal surface with abrasive materials.

- Plasma Treatment: Uses ionized gas to clean or modify the surface for better adhesion and corrosion resistance.

- Chemical Coating: Applies a chemical layer to protect against oxidation, corrosion, and wear.

powder coating

painting

plastic

brass

anodizing

Applications of surface finishing

Surface finishing is used in a wide range of industries, including:

- Automotive:Body panels, engine components, interior trim.

- Aerospace:Aircraft components, engine parts, landing gear.

- Electronics:Housings, connectors, circuit boards.

- Medical:Surgical instruments, implants, medical devices.

- Consumer goods:Appliances, tools, jewelry.

Powder coat

As machined

Anodized silver

Anodize

Anodize

Chromate Alodine

Electroplating

Surtec 650