Sheet Metal Fabrication service

XR precision specializes in sheet metal fabrication, using advanced CNC and automation technologies to enhance precision and efficiency. The company provides high-quality services for industries like aerospace, automotive, and electronics, ensuring fast delivery and exceptional product quality.

Our Sheet Metal Fabrication service

XR precision has a strong technical foundation in sheet metal fabrication, focusing on enhancing production efficiency and precision through advanced CNC technology and automation solutions. The company integrates precise cutting, stamping, and forming technologies to deliver high-quality, high-precision sheet metal services, meeting the demanding requirements of industries such as aerospace, automotive, and electronics. XR precision’s innovative technologies and reliability ensure fast delivery and exceptional product quality, even in the fabrication of complex sheet metal parts.

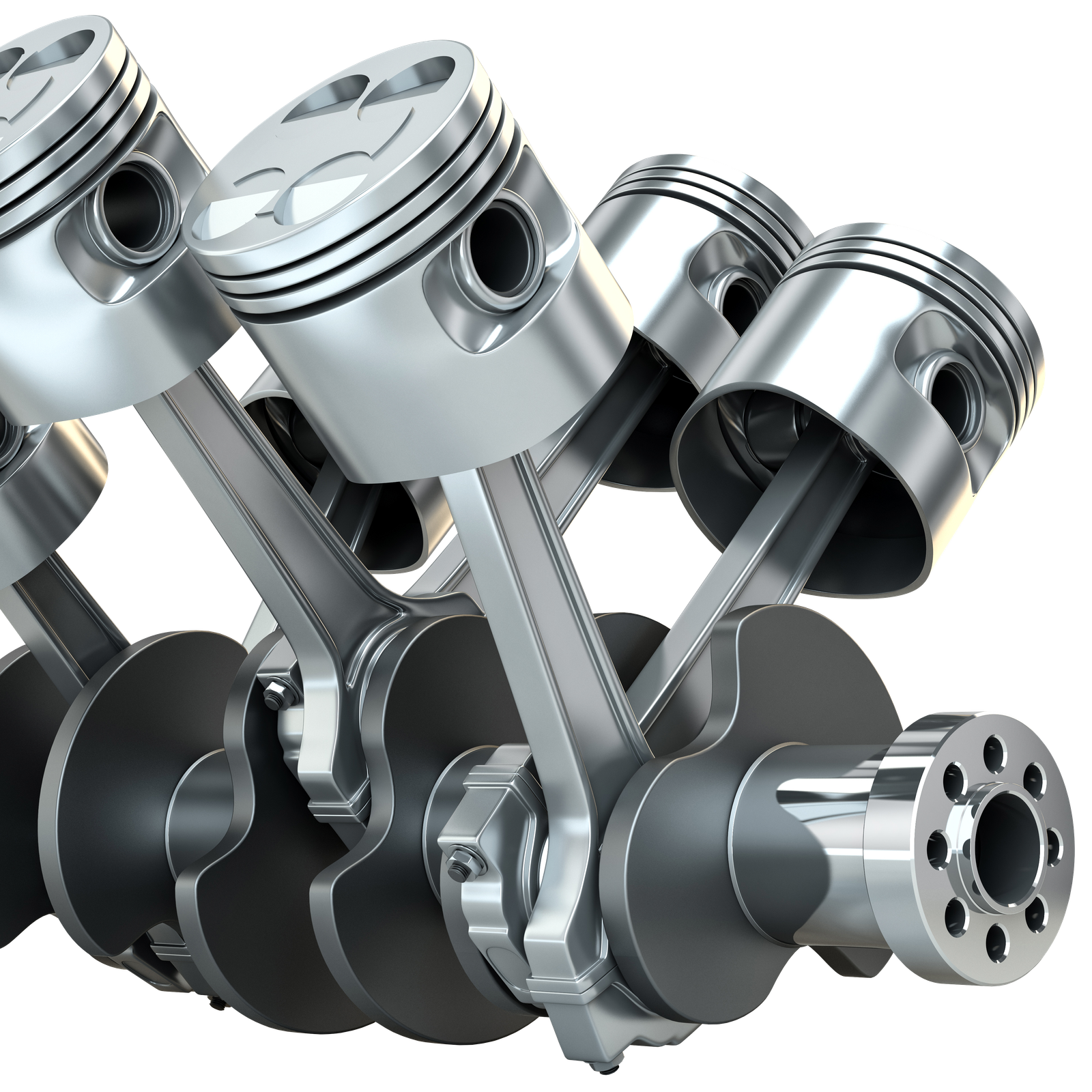

Automotive Industry

Sheet metal fabrication is extensively used in the automotive sector for manufacturing components such as body panels, chassis, and structural parts. The high precision and strength of fabricated sheet metal parts are essential for ensuring vehicle safety, performance, and durability.

Aerospace Industry

In aerospace, sheet metal fabrication is crucial for producing lightweight yet durable components such as fuselage panels, wing structures, and engine casings. The ability to achieve tight tolerances and ensure material integrity is vital to meet the high-performance standards required in aviation.

Common Materials Used in Sheet Metal Fabrication

These materials are selected based on their specific properties such as strength, weight, corrosion resistance, and conductivity to meet the needs of various industries like aerospace, automotive, electronics, and construction.

Brass

Copper

Galvanized Steel

Aluminum

Steel

Forming

- Stamping: Dies and presses are used to form complex shapes in metal.

- Drawing: Metal is drawn into shapes through a die and punch system.

Joining

- Welding: Metal parts are fused together using heat and pressure.

- Riveting: Rivets are used to connect metal pieces securely.

- Screwing: Metal parts are fastened together using screws.

Finishing & Coating

XR precision applies various finishing techniques to enhance the appearance and durability of sheet metal products. This includes cleaning, smoothing, painting, powder coating, galvanizing, electroplating, anodizing, and more to improve corrosion resistance and overall functionality before shipment.

Key Processes in Sheet Metal Fabrication

Cutting

- Laser Cutting: XR precision uses high-powered lasers for precise metal cutting.

- Waterjet Cutting: A high-pressure water stream is used to cut through metals and other materials.

- Punching: Punch presses create holes or specific shapes in metal sheets.

- Shearing: Straight-line cuts are made using a shearing machine for clean, accurate edges.

Bending

- Press Brake: Bending metal to precise angles with a press brake machine.

- Roll Forming: Continuous profiles are created by bending metal through rollers.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is used in a wide range of industries, including:

Car chassis

Car bodies

Car Components

Aircraft parts

Aircraft fuselages

Aircraft wings

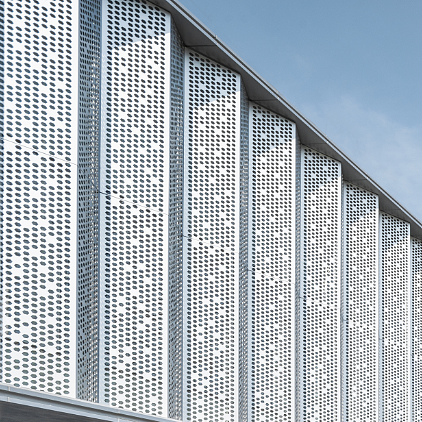

Building facades

Roofing

Ductwork

Comparing CNC Machining and Sheet Metal Fabrication

Sheet Metal Fabrication:

- Process: A forming process that shapes flat metal sheets into 3D parts.

- Materials: Primarily uses sheet metals like steel, aluminum, and stainless steel.

- Part Complexity: Best for simpler shapes and geometries.

- Tolerances: Generally less precise than CNC machining, though modern methods improve accuracy.

- Production Volume: Ideal for high-volume production due to efficiency.

- Part Thickness: Limited to the thickness of the sheet metal.

CNC Machining:

- Process: Subtractive, removes material from a solid block to form parts.

- Materials: Works with a variety of materials, including metals, plastics, and composites.

- Part Complexity: Ideal for complex, highly detailed parts.

- Tolerances: Offers very tight tolerances, suitable for precision components.

- Production Volume: Suitable for both low and high-volume production.

- Part Thickness: Can handle thicker materials.