Custom Parts Service

CNC machining is a highly versatile manufacturing process for producing high-quality, custom parts with precision and efficiency. Its versatility and ability to handle complex designs make it a valuable tool for a wide range of industries. Using computer-controlled machine tools to precisely remove material from a workpiece, creating custom-designed parts. This process is ideal for producing parts with complex geometries, tight tolerances, and high-quality surface finishes.

Key aspects of custom parts on CNC machining manufacture:

XR precision’s Custom Parts Service offers highly precise, tailor-made solutions with quick turnaround times, ensuring optimal quality and efficiency for every project.

Precision

XR precision’s Custom Parts Service delivers highly accurate, tailor-made solutions to meet the specific requirements of each project.

Efficiency

We ensure fast turnaround times, providing quick and reliable delivery without compromising on quality.

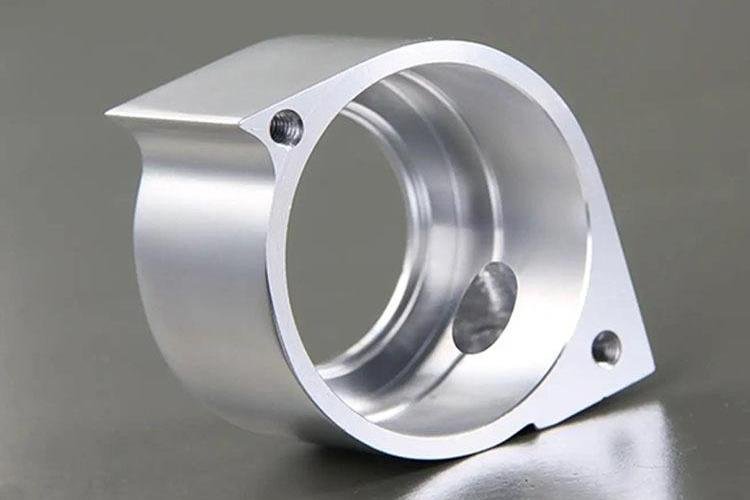

Gallery of Custom parts

Here is a sample of the CNC-machined prototypes and end-use parts we have produced for our clients.

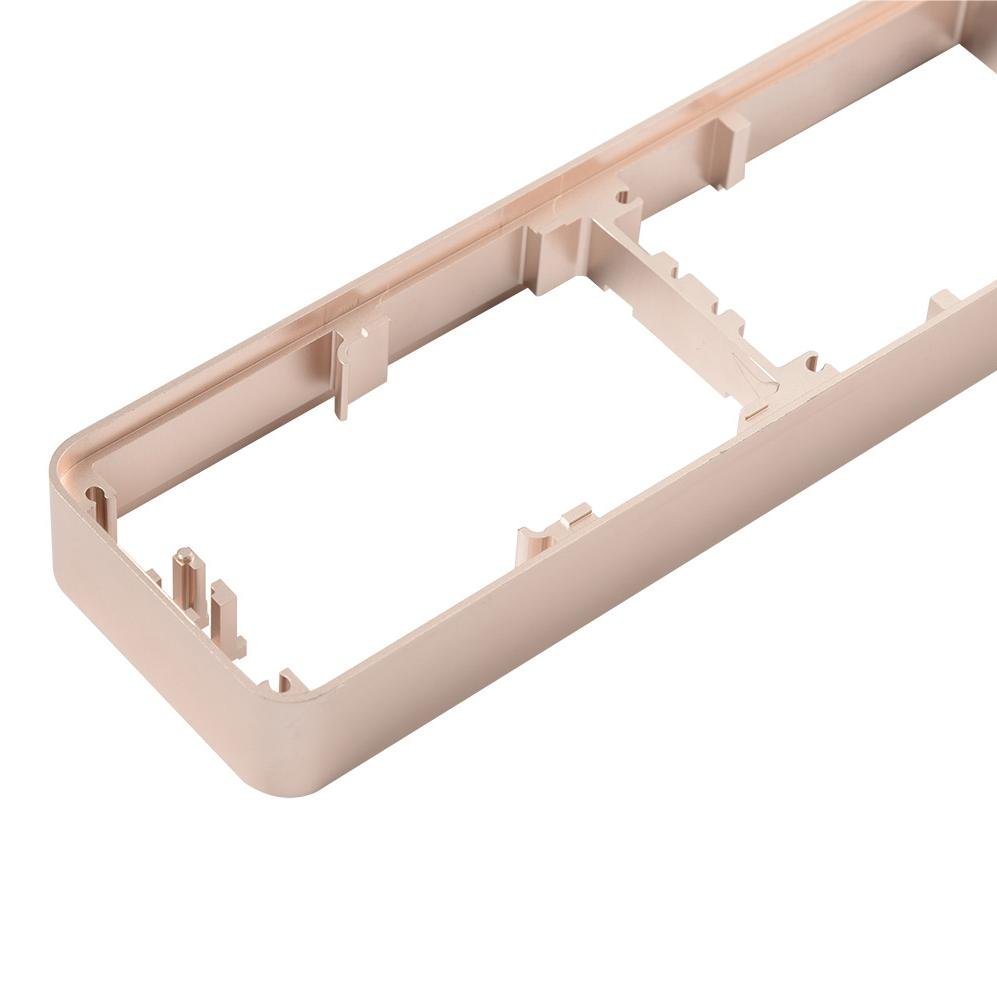

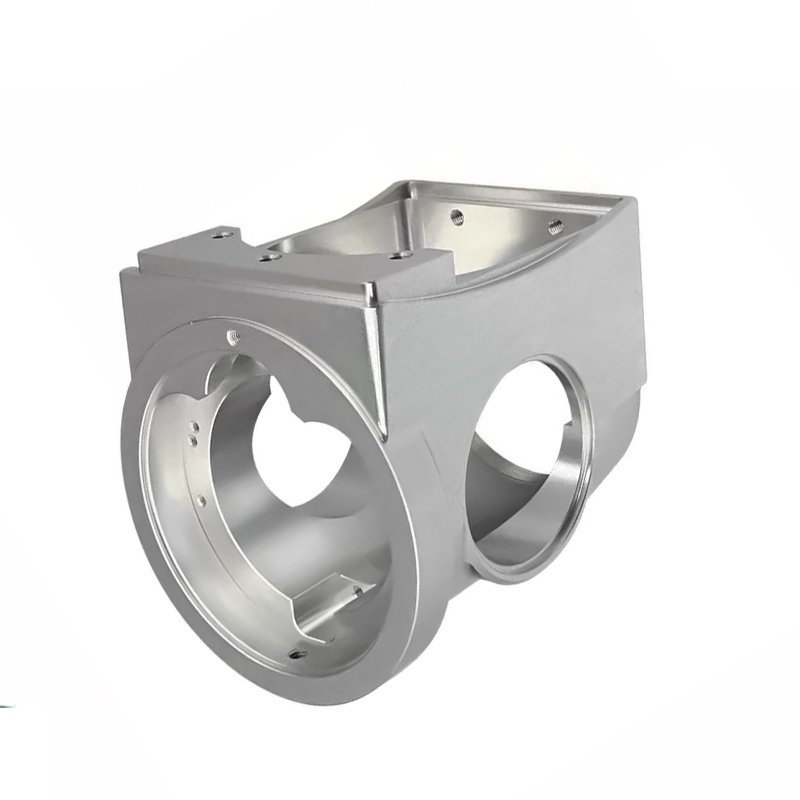

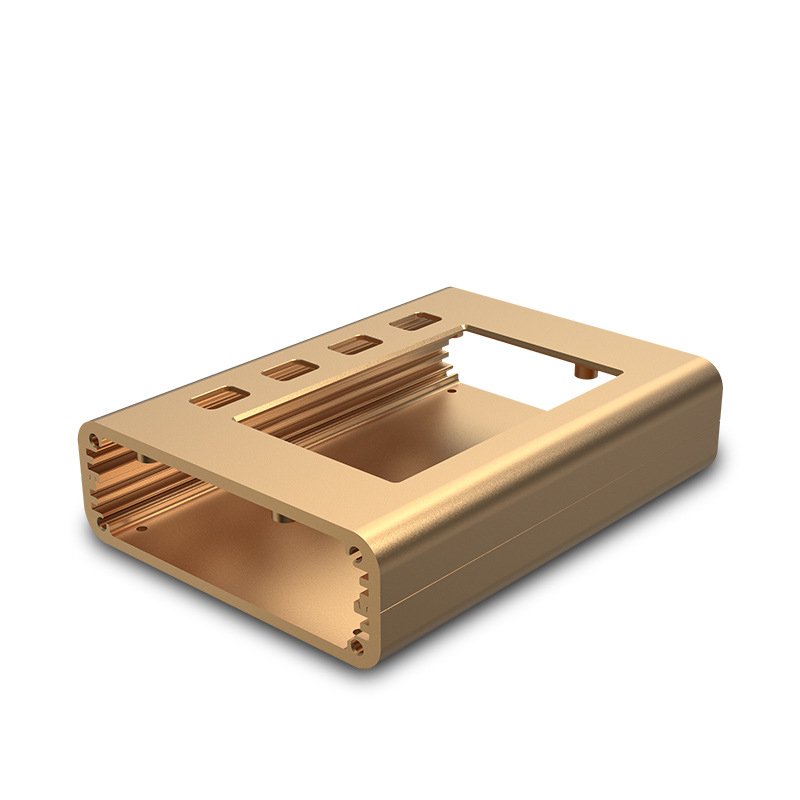

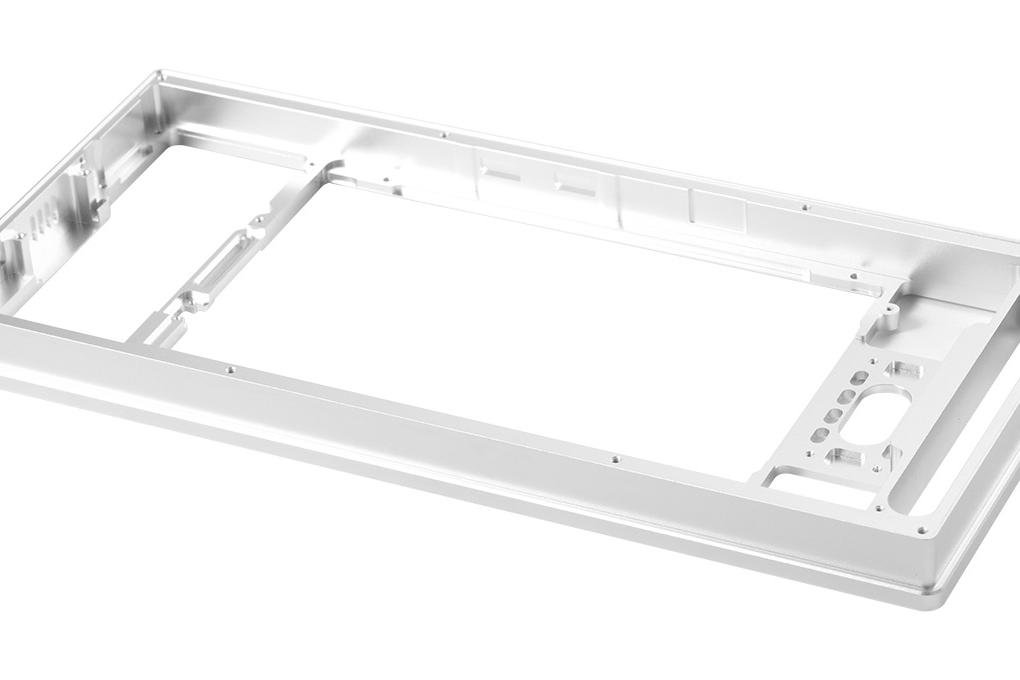

custom parts - 5

custom parts - 4

custom parts - 3

custom parts - 2

custom parts - 1

Key aspects of custom parts on CNC machining manufacture:

- Design and Programming:The process begins with a 3D CAD (Computer-Aided Design) model of the desired part. This model is then imported into CAM (Computer-Aided Manufacturing) software, which generates the CNC program that controls the machine tools.

- Material Selection:CNC machining can be used with a wide range of materials, including metals (aluminum, steel, titanium), plastics, composites, and wood. The choice of material depends on the specific requirements of the part, such as strength, weight, and corrosion resistance.

- Machining Operations:CNC machines can perform various machining operations, such as:

- Milling:Using rotating cutting tools to remove material from a workpiece.

- Turning:Rotating a workpiece against a cutting tool to create cylindrical or conical shapes.

- Drilling:Creating holes in a workpiece using drill bits.

- Grinding:Using abrasive wheels to achieve precise dimensions and smooth surface finishes.

- Advantages of CNC Machining for Custom Parts:

- High precision and accuracy:CNC machines can achieve very tight tolerances, ensuring that parts meet exact specifications.

- Complex geometries:CNC machining can produce parts with intricate shapes and complex features that are difficult or impossible to create with traditional manufacturing methods.

- Material versatility:A wide range of materials can be machined, allowing for flexibility in design and application.

- Repeatability:CNC machining ensures consistent quality and repeatability of parts, making it ideal for both prototyping and production runs.

- Automation:The automated nature of CNC machining reduces the need for manual labor, increasing efficiency and reducing costs.

- Applications of Custom CNC Machined Parts:

- Aerospace:Aircraft components, structural parts, engine components.

- Automotive:Engine parts, suspension components, interior trim.

- Medical:Surgical instruments, implants, medical devices.

- Electronics:Housings, connectors, heat sinks.

- Tooling and Fixtures:Molds, dies, jigs, and fixtures for other manufacturing processes.

aluminum

Stainless steel

plastic

brass

aluminum

CNC machining surface finishes

We provide instant quotes for a wide range of post-machining surface finishes.

CNC surface finishing is a crucial step in the manufacturing process, as it significantly impacts the performance, durability, and appearance of machined parts. By carefully selecting and applying appropriate surface treatments, CNC machined parts can be optimized the performance and longevity.

Standard -as machined, bead blast, anodized (Type II and Type III), chem film (chromate conversion), powder coat, electropolishing, electroplating, passivation and heat treatment for steel parts.

Powder coat

As machined

Anodized silver

Anodize

Anodize

Chromate Alodine

Electroplating

Surtec 650