CNC machining service

Our CNC machining service is highly specialized, meeting the strict standards for precision parts manufacturing.

Our CNC machining service capabilities

XR Precision is your partner for precision CNC machining. We cater to a variety of industries, including robotics, electric vehicles, drones, industrial automation, medical devices, agricultural machinery, and consumer products. Our comprehensive services include CNC milling, turning, drilling, and cutting, enabling us to produce a wide range of parts, such as flanges, shafts, spline, housings, and other precision-engineered components. With a vast selection of materials and advanced processes, we consistently meet exacting specifications and tight tolerances.

3 & 5 axis CNC milling

XR Precision offers a wide range of milling capabilities, including standard 3-axis mills for straightforward machining, indexed 3+2-axis mills for handling more complex geometries, and fully continuous 5-axis mills for precision multi-axis machining of intricate parts. This extensive selection of milling options ensures high-quality, customized solutions for projects across a spectrum of complexities.

3 & 5 axis CNC milling

Precision machining is a manufacturing process that involves shaping and cutting materials with extreme accuracy and precision. It is used to create parts with very tight tolerances, often measured in thousandths or even millionths of an inch. This level of precision is essential for components used in industries such as aerospace, automotive, medical devices, and electronics.

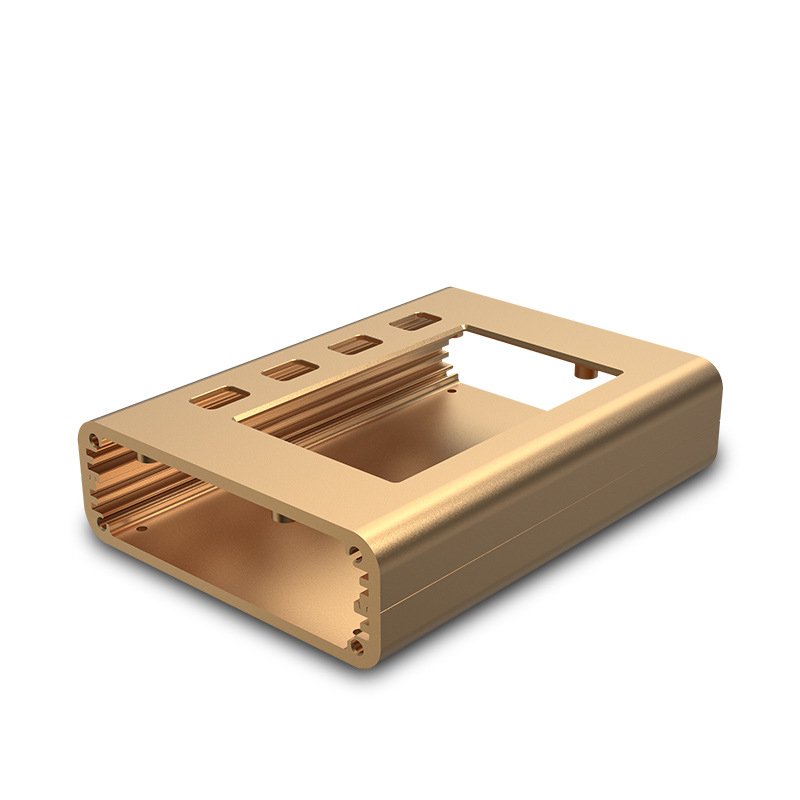

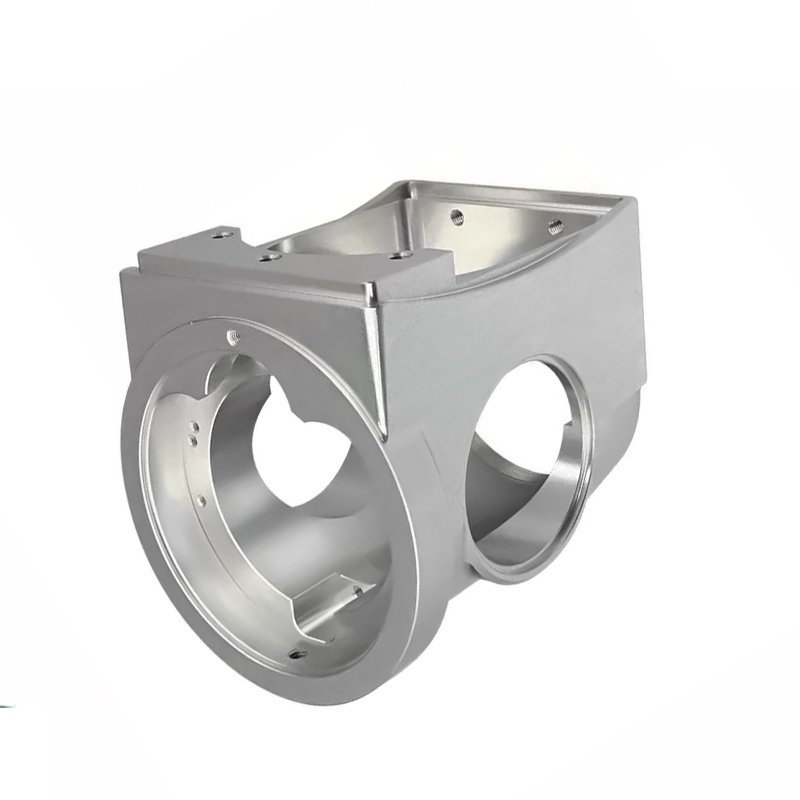

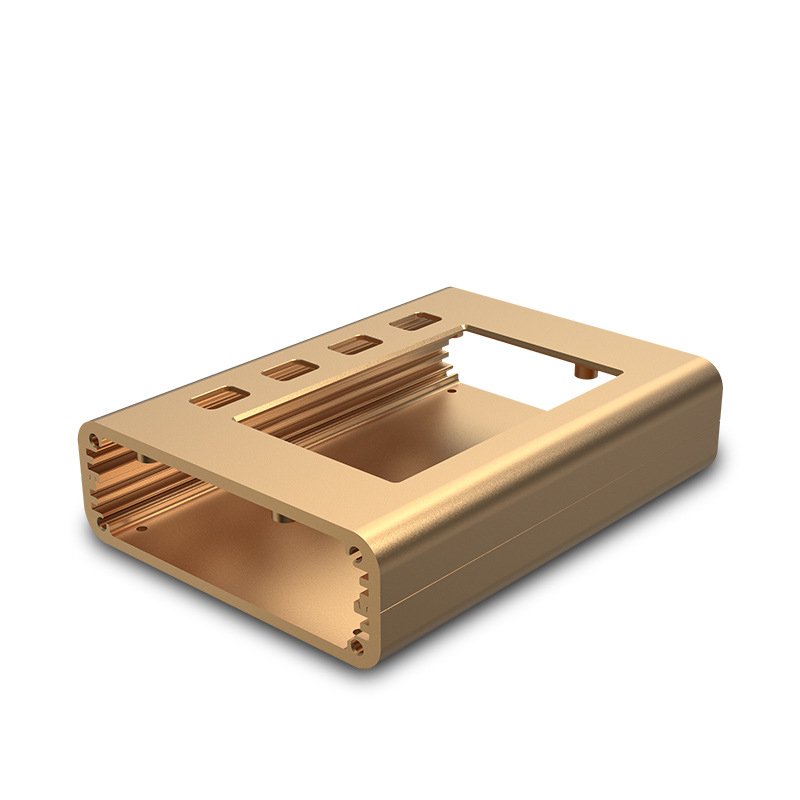

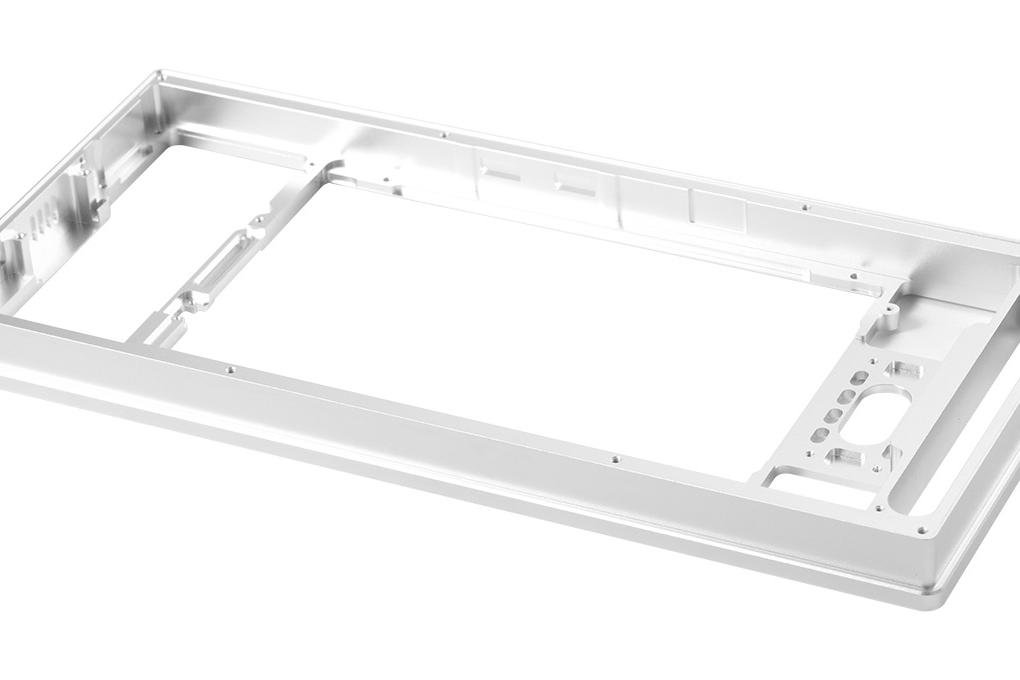

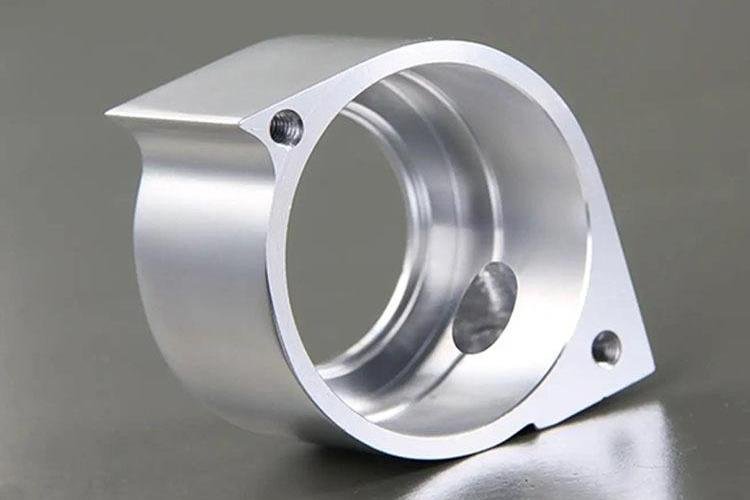

Gallery of CNC machined parts

Here is a sample of the CNC-machined prototypes and end-use parts we have produced for our clients.

sheet metal fabrication

heatsink

cnc milling parts

aluminum extrusion 2

aluminum extrusion

CNC machining materials

Here is a sample of the CNC-machined prototypes and end-use parts we have produced for our clients.

CNC Materials: How To Choose The Right Materials for CNC Machining

CNC machining’s adaptability is one of its greatest strengths. Precision CNC milling and turning can produce finished products from a wide range of raw materials, offering design engineers numerous options for prototypes and commercial products.

Most CNC-milled and turned parts utilize metals and engineering plastics due to their strength, rigidity, and ability to withstand the rapid material removal of modern CNC technology. Let’s explore the most commonly used metals in CNC machining.

Metal: Aluminum, stainless steel, steel, brass, copper, bronze, titanium, and alloy.

Plastics: Acrylic, Nylon, polycarbonate, ABS, Delrin, POM, PP, PMMA, PTFE(Teflon), PEI, PEEK, HDPE, UHMW.

aluminum

Stainless steel

plastic

brass

aluminum

CNC machining surface finishes

We provide instant quotes for a wide range of post-machining surface finishes.

CNC surface finishing is a crucial step in the manufacturing process, as it significantly impacts the performance, durability, and appearance of machined parts. By carefully selecting and applying appropriate surface treatments, CNC machined parts can be optimized the performance and longevity.

Standard -as machined, bead blast, anodized (Type II and Type III), chem film (chromate conversion), powder coat, electropolishing, electroplating, passivation and heat treatment for steel parts.

Powder coat

As machined

Anodized silver

Anodize

Anodize

Chromate Alodine

Electroplating

Surtec 650